The Ultimate Guide to Printing Methods for Greaseproof Paper

By Alysse Phily · 18. July 2024

Wondering about the best printing methods for greaseproof paper? This guide will help you understand the key techniques, including Pantone, CMYK, and more.

You’ll learn which method is ideal for your packaging needs, balancing cost, quality, and branding.

Key Takeaways

- Understanding the differences between Pantone and CMYK colour systems is crucial for achieving precise colour matching or photorealistic designs in greaseproof paper printing.✨

- Advanced printing techniques such as digital, flexographic, and offset printing offer unique advantages in print quality, durability, and scalability for custom printed greaseproof paper.

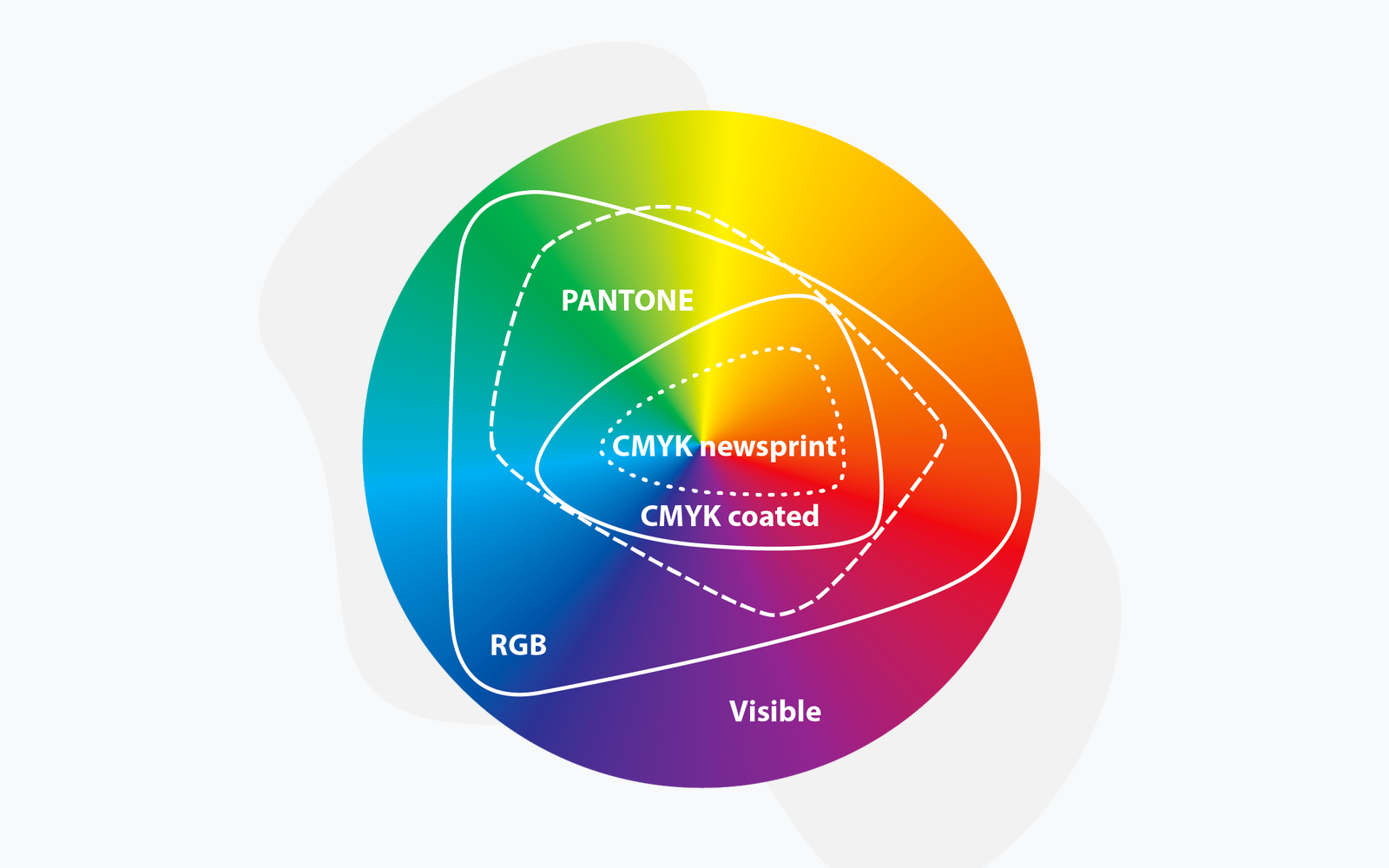

Pantone vs. CMYK Colour Systems

cmyk pantone rgb colorspace

cmyk pantone rgb colorspace

Understanding the difference between Pantone and CMYK colour systems is crucial in bringing your greaseproof paper designs to life.

These two primary methods for printing on greaseproof paper each have their unique strengths and applications.

Pantone, known for its precision and consistency, is the go-to choice for brands that require exact colour matching across various materials and print runs.

With over 1000 shades in the Pantone Matching System (PMS), it offers a broad spectrum for precise colour selection.

On the other hand, CMYK excels in producing photorealistic and multi-colour imagery, making it ideal for complex designs.

While Pantone uses a ‘spot colour’ method, printing each colour individually (which can be more costly), CMYK’s layering technique often proves more economical for intricate, full-colour designs.

We will explore each printing method deeply to assist you in determining which one best aligns with your greaseproof paper printing needs.

Pantone Colour System

📏 The Pantone colour system is renowned for its ability to deliver precise and consistent colours, making it an invaluable tool for businesses that prioritise brand identity and print colour accuracy in their greaseproof paper printing.

This standardised system ensures that manufacturers in different locations can achieve consistent colour matches, which is critical for maintaining a unified brand image across various packaging materials and marketing collateral.

Pantone’s extensive colour palette ensures precise replication every time, whether you’re printing with white paper unlimited colours or aiming for a light pink print on a kraft brown background.

One of the key advantages of the Pantone system is its suitability for producing vibrant tones and special finishes, such as metallic or neon colours.

This capability is particularly beneficial for brands looking to create eye-catching, premium packaging that stands out on the shelf.

For designs requiring one or two specific colours, Pantone is the ideal choice, guaranteeing that the colours match exactly with your brand’s requirements. 🌟

CMYK Color System

The CMYK colour system, short for Cyan, Magenta, Yellow, and Black, is a powerhouse when it comes to creating complex and visually stunning prints on greaseproof paper.

This system works by combining these four colours in various percentages to achieve a wide range of shades and hues.

The beauty of CMYK lies in its ability to produce virtually unlimited colour possibilities, making it the go-to choice for advanced graphics and intricate designs.

CMYK’s versatility allows you to bring your vision to life, whether you’re aiming to create subtle colour gradients or reproduce photorealistic images on your greaseproof paper packaging.

However, it’s important to note that while CMYK offers unparalleled flexibility in colour reproduction, there can be slight variations in the final output between different printers, even when using the same document.

This is due to factors such as printer calibration, paper quality, and environmental conditions. For businesses that require absolute colour consistency across all their printed materials, this might be a consideration.

Nevertheless, for most applications, especially those involving complex designs or full-colour imagery, the CMYK system provides an excellent balance of versatility and cost-effectiveness.

Its ability to create a vast array of unlimited print colours from just four base inks makes it an efficient and popular choice for greaseproof paper printing, particularly for businesses looking to make a bold visual impact with their packaging. 🎨

Advanced Printing Techniques for Greaseproof Paper

As we further explore the world of greaseproof paper printing, we will examine the advanced techniques that can significantly enhance your packaging game.

These cutting-edge methods not only enhance the appearance of your greaseproof paper but also significantly boost its functionality, allowing for precise and vibrant designs that can dramatically increase brand visibility.

From the versatility of digital printing to the high-quality output of offset printing, and the unique capabilities of screen printing, each technique offers its own set of advantages.

Understanding these advanced printing methods for greaseproof paper will empower you to make informed decisions about your custom printed packaging, ensuring that your packaging not only protects your products but also serves as a powerful marketing tool.

We will examine the specifics of each technique, discovering how they can be used to create standout greaseproof paper products.

Digital Printing

🖨️ Digital printing has revolutionised the world of greaseproof paper production, offering unparalleled flexibility and cost-effectiveness, especially for short runs and custom designs.

This method shines when it comes to creating intricate and vibrant designs with precision, making it the perfect choice for businesses looking to produce complex, eye-catching packaging.

One of the most significant advantages of digital printing is its ability to accommodate quick adjustments and updates to designs without the need for extensive setup.

Businesses that frequently update their branding or run seasonal promotions will find this feature particularly valuable.

Digital printing, whether on kraft paper, white paper with unlimited colours, or in creating custom printed takeaway packaging, offers the versatility to realise your vision with stunning clarity and detail.

Its low setup cost and rapid turnaround times make it an excellent option for businesses of all sizes, from startups testing new packaging designs to established brands looking to produce small batches of specialty items.

Flexographic Printing

Flexographic printing, often referred to as “flexo”, is a versatile and efficient method that has become increasingly popular for printing on greaseproof paper, especially for larger orders.

This technique utilises flexible plates that can adapt to a variety of substrates, including the smooth surface of greaseproof paper.

The flexibility of these plates allows for consistent and high-quality prints across large volumes, making flexographic printing an excellent choice for businesses looking to produce custom printed greaseproof paper in bulk.

One of the standout features of flexographic printing is its use of food-safe, water-based inks.

This characteristic is particularly crucial for greaseproof paper applications in the food industry, where safety is paramount. The water-based inks offer several benefits:

- They ensure the safety of the packaging

- They contribute to the vibrancy of the prints

- They allow for eye-catching designs that don’t compromise on food safety standards

Moreover, flexographic printing excels in producing sharp image reproduction, which is ideal for large volumes of greaseproof paper due to its stable ink performance.

Flexographic printing delivers consistent, high-quality results that can withstand the demands of food packaging and presentation, whether it’s intricate logos, detailed product information, or bold branding elements. 🖌️

Offset Printing

Offset printing stands out as a premier choice for businesses seeking top-notch print quality on their greaseproof paper products. This technique is renowned for its ability to produce:

- Sharp, vibrant images and text

- Visually stunning packaging that captures attention and enhances brand perception

- Exceptionally crisp and detailed prints

- Precision when printing intricate designs, fine text, or complex colour gradients on greaseproof paper

One of the key advantages of offset printing is its consistency across large print runs.

This makes it an excellent choice for businesses that require high-volume orders of custom printed greaseproof paper without compromising on quality.

Offset printing ensures consistent high-standard print quality on every sheet, whether it’s sandwich wraps, food liners, or custom takeaway packaging.

The technique’s ability to achieve precise and sharp prints on greaseproof paper also means that your branding elements, such as logos and product information, will be reproduced with exceptional clarity and accuracy.

For businesses looking to make a significant impact with their packaging and maintain a premium brand image, offset printing on greaseproof paper offers an unparalleled combination of quality and consistency. 🎯

Customization Options for Printed Greaseproof Paper

Customization is the key to making your greaseproof paper packaging stand out in a crowded marketplace.

The options for personalising your greaseproof paper are virtually limitless, allowing you to create packaging that not only protects your products but also serves as a powerful branding tool.

Some ways to customise your greaseproof paper include:

- Choosing unique sizes and shapes

- Using vibrant colours

- Incorporating intricate designs

- Adding your logo or brand name

Custom printed greaseproof paper offers an economical way to enhance brand recognition and create a memorable customer experience with bespoke greaseproof paper.

Whether you opt for single or two-colour prints using the Pantone colour system or decide to explore more complex designs with CMYK printing, the possibilities for creativity are endless.

While exploring the various customization options, remember to let the intended application of your greaseproof paper, whether for baking or packaging, guide your choices for optimal functionality and visual appeal.

Logo and Design Features

© Limepack Branded Greaseproof Paper

© Limepack Branded Greaseproof Paper

Incorporating your logo and unique design features into your greaseproof paper is where the magic of brand recognition truly happens.

Custom printed greaseproof paper offers an unparalleled opportunity to showcase your brand identity while providing a functional product.

Whether you’re wrapping:

- fries

- burgers

- burritos

- baguettes

- sandwiches

- or any other food item

Your greaseproof paper becomes a canvas for your brand story.

With high-quality printing techniques, your logo and design elements can be reproduced with stunning clarity and vibrancy, ensuring that every interaction with your packaging reinforces brand recall.

The beauty of custom printing lies in its versatility – you can opt for a simple, elegant logo placement or create an all-over pattern that turns your greaseproof paper into a work of art. 🌟

By thoughtfully incorporating your logo and design features, you transform a simple piece of packaging into a powerful marketing tool that works tirelessly to promote your brand with every use. 🛠️

Summary

As we wrap up our comprehensive guide to top printing methods for greaseproof paper, it’s clear that this versatile material offers a wealth of opportunities for businesses to enhance their packaging and branding efforts.

From the fundamental choice between single-sided and double-sided printing to the advanced techniques of digital, flexographic, and offset printing, each method presents unique advantages that can be tailored to your specific needs.

The decision between Pantone and CMYK colour systems further allows for precise colour matching or vibrant, complex designs, ensuring that your greaseproof paper truly reflects your brand identity.

Throughout this journey, we’ve explored the importance of customization options such as bespoke sizes, tinting, and logo integration, which can transform a simple piece of packaging into a powerful marketing tool.

We’ve also delved into crucial quality considerations, including paper thickness, ink durability, and environmental factors, emphasising the need for a balance between functionality, aesthetics, and sustainability.

By keeping these factors in mind and following the practical tips provided, you’re now equipped to make informed decisions about your greaseproof paper printing projects.

Remember, the key to success lies in understanding your specific needs, experimenting with different options, and continuously innovating to stay ahead in the competitive world of food packaging and presentation.

Frequently Asked Questions

How do I choose between Pantone and CMYK colour systems for my greaseproof paper printing?

Choose Pantone for exact colour matching and consistency, especially for brand colours or simple designs, and opt for CMYK for complex designs, photorealistic images, or a wide range of colours in your design. CMYK is more cost-effective for multi-color prints, while Pantone ensures precise colour reproduction across different print runs.

What are the advantages of digital printing for greaseproof paper?

The advantages of digital printing for greaseproof paper include cost-effectiveness for short runs, the ability to produce intricate and vibrant designs with precision, and quick turnaround times. It also allows for easy design updates and customization without the need for new printing plates, making it ideal for businesses that frequently change their packaging designs or require small batches of custom prints.

What safety precautions should I take when printing on greaseproof paper?

When printing on greaseproof paper, ensure proper supervision to prevent malfunctions and fire hazards. Use toner suitable for high-heat environments and allow printed sheets to cool down before handling to avoid smudging and ensure safety. It’s also important to maintain proper ventilation and follow the printer manufacturer’s guidelines for specialty papers. Conduct test prints before large runs to check compatibility and adjust settings as needed.